FU独特的分离过滤器是旋风分离与过滤两个功能的组合产品,具有节省安装空间,减轻滤芯负荷的优点。旋风分离组件可以去除大部分的液态油水及大的固体颗粒,滤芯再进一步除油除尘,分离器滤芯一般选用P级或M级。产品可以安装在紧凑空间的机器内部,冷冻式干燥机前,空分设备后以及其他应用场合。

The unique advantage of the combination of two cyclone filter elements is that they can reduce the installation space and reduce the load of the two cyclone filters. The cyclone separation module can remove most of the liquid oil-water and large solid particles, and the filter element can further remove oil and dust. The filter element of the separator generally adopts grade P or m. The product can be installed inside the machine in a compact space, in front of the freeze dryer, behind the air separation equipment and other applications.

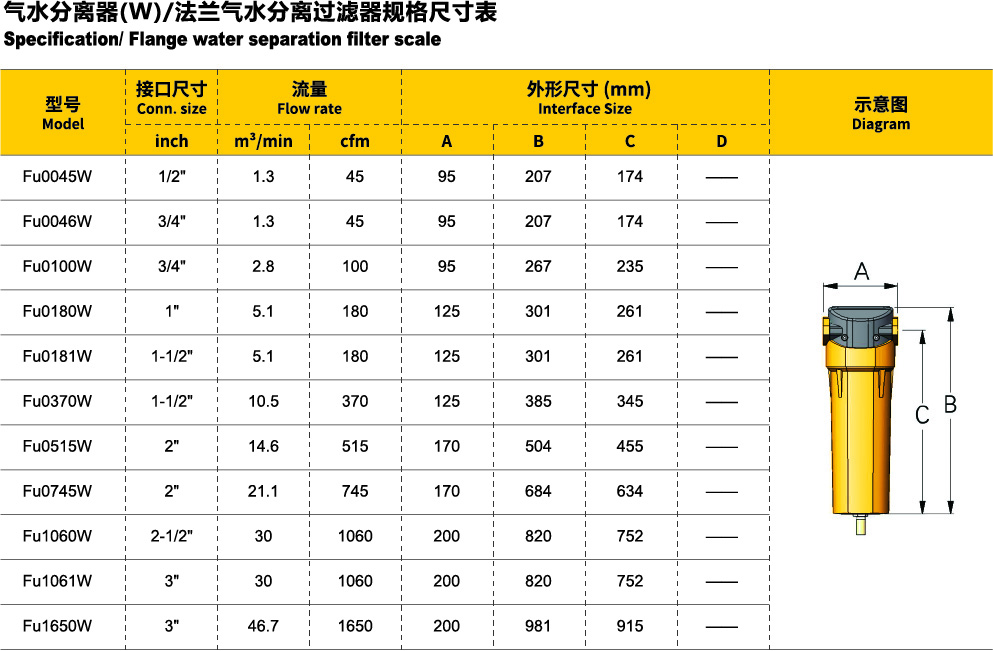

技术参数:Technical parameters

工作压力:0.7-1.6MPa Working pressure:0.7-1.6MPa

工作温度:100℃ Max Opereting temperature:100℃ Max

压缩空气过滤器的工作原理

Working principle of compressed air filter

大气中含有水蒸气,碳氢化合物及固体颗粒(每立方米的空气中含有大约1亿4千万个固体颗粒),这些杂质随着空气被吸入空压机中,然后和残留的润滑油一起进入压缩空气管网。这些污染物如果不能及时得到处理将会导致管道腐蚀,危害到生产设备及工具的灵敏度和寿命,并对制造产品的质量造成影响。

The atmosphere contains water vapor, hydrocarbons and solid particles (about 140 million solid particles per cubic meter of air). These impurities are sucked into the air compressor with the air, and then enter the compressed air pipe network together with the residual lubricating oil. If these pollutants cannot be treated in time, they will lead to pipeline corrosion, endanger the sensitivity and service life of production equipment and tools, and affect the quality of manufactured products.

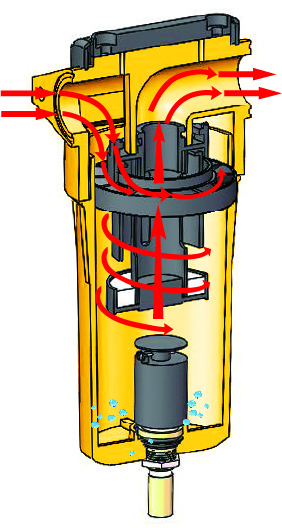

当待处理的压缩空气进入过滤器时,流速放缓,大颗粒的液滴在重力作用下掉落下来,还有一些液滴和固体颗粒在通过玻纤滤料层时被直接拦截下来。较小直径的液滴和固体颗粒随气流通过滤芯时,因惯性碰撞被滤料捕捉并逐渐凝聚成更大的液滴流下来,更小的固体和液体颗粒不随气流改变方向,只是在做布朗运动,一旦接近滤料时,受玻纤的静电引力影响而被吸附在滤料上。过滤出来的油水聚集在过滤器的底部,经排水器排出。为了保护环境,排出的油水必须要有专门的容器收集,切勿直接排放到公共污水管。

When the compressed air to be treated enters the filter, the flow rate slows down, the droplets of large particles fall down under the action of gravity, and some droplets and solid particles are directly intercepted when passing through the glass fiber filter material layer. When the smaller diameter droplets and solid particles pass through the filter element with the air flow, they are captured by the filter material due to inertial collision and gradually condensed into larger droplets. The smaller solid and liquid particles do not change the direction with the air flow, but only do Brownian motion. Once they approach the filter material, they are adsorbed on the filter material under the influence of the electrostatic attraction of glass fiber. The filtered oil and water is collected at the bottom of the filter and discharged through the drain. In order to protect the environment, the discharged oil and water must be collected in a special container and must not be directly discharged to the public sewage pipe.

过滤器的能效

Energy efficiency of filters

压缩空气过滤器的压力损失由固有的压力损失和逐渐增大的压力损失组成。固有压力损失由过滤器壳体结构和壳体与滤芯之间的接口产生。增量的压力损失由过滤器滤芯工作过程中逐渐被污染物堵塞而产生。提供优化的压缩空气通道是降低系统运行费用的关键。

过滤器接口:

同一个过滤器具有多种接口尺寸可供选择,能同时满足系统不同和流量的要求,增加了客户选择机会和减少安装费用。

紧凑、轻巧

先进的滤芯设计理念可使用过滤器更小,更紧凑。同时允许过滤器安装在狭窄的空间里。

完全防腐

FU过滤器壳体经过黑色电泳,优越的防腐性能提供10年的质量保证。

按时更换滤芯的好处

·确保高质量的压缩空气

·保护吸附式干燥器吸附床

·保护下游设备

·减少运行费用

提高生产力和盈利能力

不更换滤芯的后果有哪些

破坏吸附式干燥器的吸附床,导致非计划更换吸附剂

·腐蚀储气罐和输送管网堵塞和冻结阀门和空气马达

·从阀门、气缸排放的污染物会形成一个不健康的工作环境,存在潜在的人员流失以及由于健康而造成的经济损失

·损坏机器

·生产流程效率低下

·合格率低

增加制造成本,增加停机时间

过滤器配置了压差表,而且表上的指针位于绿色区域,却为什么还需要更换滤芯?

由于滤芯中的过滤纤维在使用过程中逐渐变脆,即使一个很小的孔也会导致过滤介质断裂,这时污染物未经过滤就进入下游压缩空气系统中。如果这种现象真的发生,由于过滤器前后压差不大,压差表上的指针会始终处于绿色区域,滤芯不会被及时更换直至用户在下游发现污染物,这种情况发生以后,即使更换了滤芯,在相当长的一段时间内下游管线中还是会有污染物存在。