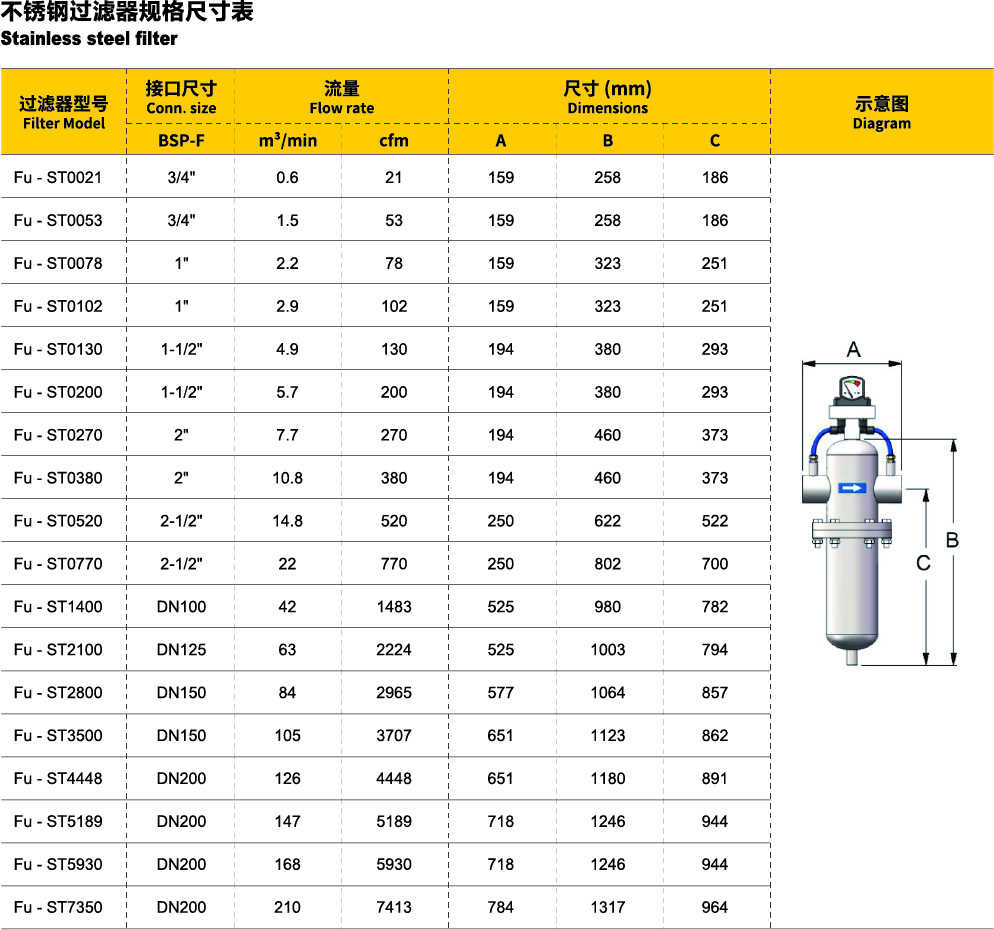

当对压缩空气质量高的时候,系统要釆用不锈钢管道和不锈钢过滤器。Fu提供不锈钢过滤器采用高精度制造工艺,壳体采用304或316L不锈钢制造,内外表面层镜面拋光处理,防腐蚀,结构符合空气动力学原理,确保将过滤介质压降降到最低。核心是我们的高效滤芯,可以满足不同行业的需求,可提供高的过滤效率和非常低的压降,最终保证了纯净的压缩空气和低的运营成本。广泛应用于各种对气体要求高的行业,例如:半导体制造、医疗、制药及食品加工等。

When the quality of compressed air is high, the system shall adopt stainless steel pipes and stainless steel filters. The stainless steel filter provided by Fu adopts high-precision manufacturing process, the shell is made of 304 or 316L stainless steel, the inner and outer surface layers are mirror polished, anti-corrosion, and the structure conforms to the aerodynamic principle to ensure that the pressure drop of the filter medium is minimized. The core is our high-efficiency filter element, which can meet the needs of different industries, provide high filtration efficiency and very low pressure drop, and finally ensure pure compressed air and low operating cost. It is widely used in various industries with high gas requirements, such as semiconductor manufacturing, medical treatment, pharmaceutical and food processing.

不锈钢除菌类过滤器(可以通蒸汽)

Stainless steel sterilizing filter (can be filled with steam)

在生物制药、食品饮料、电子化工等行业中,压缩空气过滤都需要使用无菌或者高纯度过滤以满足工艺需要,达到FDA、GMP等标准。Fu提供不锈钢除菌过滤器,壳体釆用304或316卫生级不锈钢制造,内外表面层铙面抛光处理,防腐蚀,无死角、无残留,配上快装卡盘,便于维护。滤芯采用超大面积的聚氟乙烯(PTFE)除菌滤纸,快装式结构,便于安装,根据实际情况每周或每月1~2次,每次30分钟,使用120-140°C洁净蒸汽定期灭菌。

In biopharmaceutical, food and beverage, electronic and chemical industries, compressed air filtration requires aseptic or high-purity filtration to meet the needs of the process and meet the standards of FDA and GMP. Fu provides stainless steel sterilizing filter. The shell is made of 304 or 316 sanitary stainless steel. The internal and external surfaces are polished to prevent corrosion, without dead corners and residues. It is equipped with quick loading chuck to facilitate maintenance. The filter element adopts a large area of polyfluoroethylene (PTFE) sterilization filter paper and a quick installation structure, which is easy to install. According to the actual situation, it is sterilized regularly with 120-140 ° C clean steam once or twice a week for 30 minutes each time.

技术参数:Technical parameters

压力范围:0.05-1.0MPa Pressure range: 0.05-1.0mpa

过滤精度:0.01um Filtering accuracy: 0.01um

过滤效率:99.99% Filtration efficiency: 99.99%

进气温度:5-80℃ Inlet air temperature: 5-80 ℃

环境温度:2-60℃ Ambient temperature: 2-60 ℃

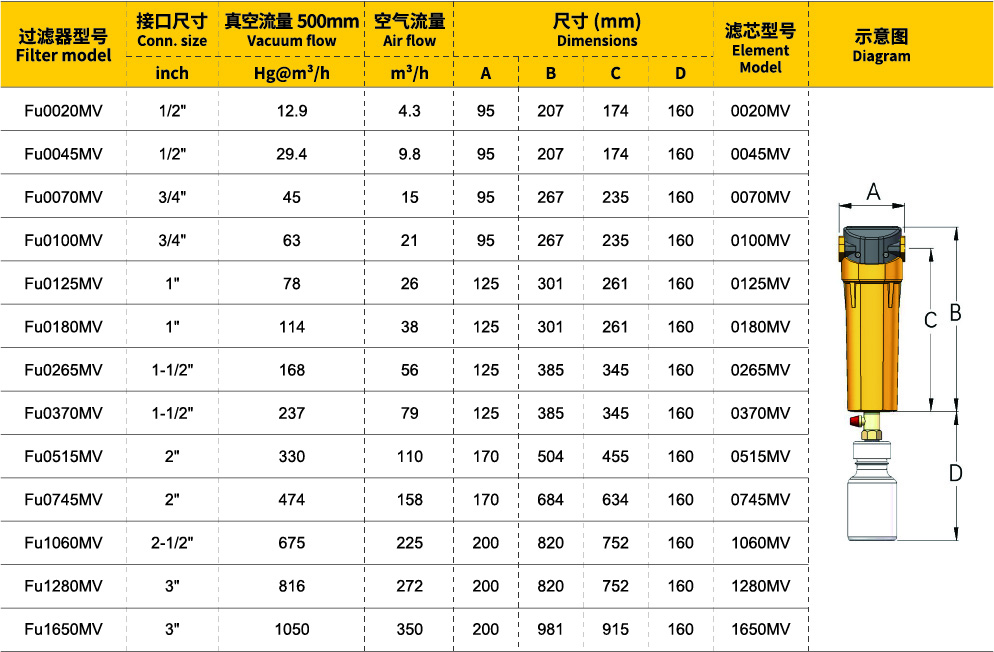

医用真空除菌过滤器

Medical vacuum sterilization filter

医用真空除菌过滤器主要用于医院无菌病房的负压系统。医院的真空吸引系统是现代化医院必备的系统设备。真空吸引系统从手术室吸引的带有细菌的气体打〖中,会对周围的环境造成污染,是细菌传播的途径之一。Fu提供的真空除菌过滤器可以有效拦截细菌并收集起来,避免细菌的污染。除菌过滤器同样适用于无尘无菌的试验室和车间。医用真空过滤器壳体釆用铝合金制造,内表层电泳外理,防腐蚀性能强;外表面喷粉处理,涂层质量好、耐腐蚀、机械性能强。

Medical vacuum sterilization filter is mainly used in the negative pressure system of hospital sterile ward. The vacuum suction system of hospital is the necessary system equipment of modern hospital. The vacuum suction system draws bacteria laden gas from the operating room It will pollute the surrounding environment and is one of the ways of bacterial transmission. The vacuum sterilization filter provided by Fu can effectively intercept and collect bacteria to avoid bacterial pollution. The sterilization filter is also suitable for dust-free and sterile laboratories and workshops. The shell of the medical vacuum filter is made of aluminum alloy, with electrophoretic and external treatment on the inner surface and strong corrosion resistance; the outer surface is sprayed with powder, with good coating quality, corrosion resistance and strong mechanical performance.

压缩空气过滤器的工作原理

Working principle of compressed air filter

大气中含有水蒸气,碳氢化合物及固体颗粒(每立方米的空气中含有大约1亿4千万个固体颗粒),这些杂质随着空气被吸入空压机中,然后和残留的润滑油一起进入压缩空气管网。这些污染物如果不能及时得到处理将会导致管道腐蚀,危害到生产设备及工具的灵敏度和寿命,并对制造产品的质量造成影响。

The atmosphere contains water vapor, hydrocarbons and solid particles (about 140 million solid particles per cubic meter of air). These impurities are sucked into the air compressor with the air, and then enter the compressed air pipe network together with the residual lubricating oil. If these pollutants cannot be treated in time, they will lead to pipeline corrosion, endanger the sensitivity and service life of production equipment and tools, and affect the quality of manufactured products.

当待处理的压缩空气进入过滤器时,流速放缓,大颗粒的液滴在重力作用下掉落下来,还有一些液滴和固体颗粒在通过玻纤滤料层时被直接拦截下来。较小直径的液滴和固体颗粒随气流通过滤芯时,因惯性碰撞被滤料捕捉并逐渐凝聚成更大的液滴流下来,更小的固体和液体颗粒不随气流改变方向,只是在做布朗运动,一旦接近滤料时,受玻纤的静电引力影响而被吸附在滤料上。过滤出来的油水聚集在过滤器的底部,经排水器排出。为了保护环境,排出的油水必须要有专门的容器收集,切勿直接排放到公共污水管。

When the compressed air to be treated enters the filter, the flow rate slows down, the droplets of large particles fall down under the action of gravity, and some droplets and solid particles are directly intercepted when passing through the glass fiber filter material layer. When the smaller diameter droplets and solid particles pass through the filter element with the air flow, they are captured by the filter material due to inertial collision and gradually condensed into larger droplets. The smaller solid and liquid particles do not change the direction with the air flow, but only do Brownian motion. Once they approach the filter material, they are adsorbed on the filter material under the influence of the electrostatic attraction of glass fiber. The filtered oil and water is collected at the bottom of the filter and discharged through the drain. In order to protect the environment, the discharged oil and water must be collected in a special container and must not be directly discharged to the public sewage pipe.